In-Depth Analysis: Structure and Pressure Regulation Principles of Natural Gas Storage Tanks

Structure of Natural Gas Storage Tanks:

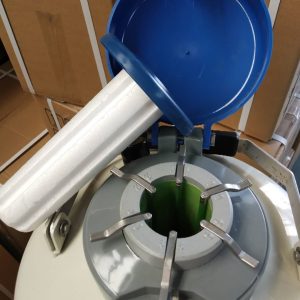

Natural gas storage tanks are designed with a double-layer structure. The inner tank is responsible for storing the cryogenic liquid and must withstand the pressure of the medium. It is made from cryogenic-resistant alloy steel (0Cr18Ni9). The outer shell acts as a protective layer for the inner tank. There is a designated space between the inner tank and the outer shell, creating an insulated area that bears the weight of the inner tank, the medium, and the vacuum negative pressure of the insulation layer. The outer shell, which does not directly contact the cryogenic section, is made from container-grade steel. The insulation layer is usually filled with perlite and maintained under high vacuum conditions. The evaporation rate of cryogenic storage tanks is typically less than 0.2%.

Principles of Pressure Regulation in Cryogenic Storage Tanks:

The liquid in a natural gas storage tank is dispensed using the tank’s self-generated pressure as the driving force. As the liquid is drawn from the tank, the liquid level decreases, increasing the vapor space and causing a drop in internal pressure. To maintain stable pressure and meet process requirements, gas must be continually added to the tank.

A pressure-building vaporizer and a pressure-building valve are installed at the bottom of the tank. The vaporizer is an ambient air vaporizer positioned below the lowest liquid level of the natural gas storage tank. The pressure-building valve functions in the opposite manner of a pressure-reducing valve. It opens when the outlet pressure falls below a set point and closes when the pressure rises above the set value.

The pressure-building process works as follows: When the tank’s internal pressure drops below the set point of the pressure-building valve, the valve opens, allowing liquid from the tank to slowly flow into the vaporizer due to the difference in liquid levels. In the vaporizer, the liquid gasifies, and the resulting gas flows through the pressure-building valve and vapor space piping, replenishing the tank. As gas continues to be added, the tank’s internal pressure gradually increases. Once the pressure exceeds the set point of the pressure-building valve, the valve closes, and the pressure in the vaporizer prevents further liquid from entering, concluding the pressure-building process.

WOBO Industrial Group Cryochains

WOBO Industrial Group Cryochains

HelloPlease log in