Cryogenic Box

Revolutionize Metal Treatment with Ultra-Low Temperature SolutionsCryogenic treatment box is used to expose materials to extremely low temperatures, typically around -190°C (-310°F). This process enhances the properties of metals and alloys, such as increasing wear resistance and relieving residual stresses. The treatment is commonly applied to steel and other metal components to improve their durability and performance.

You may also be interested in these products.

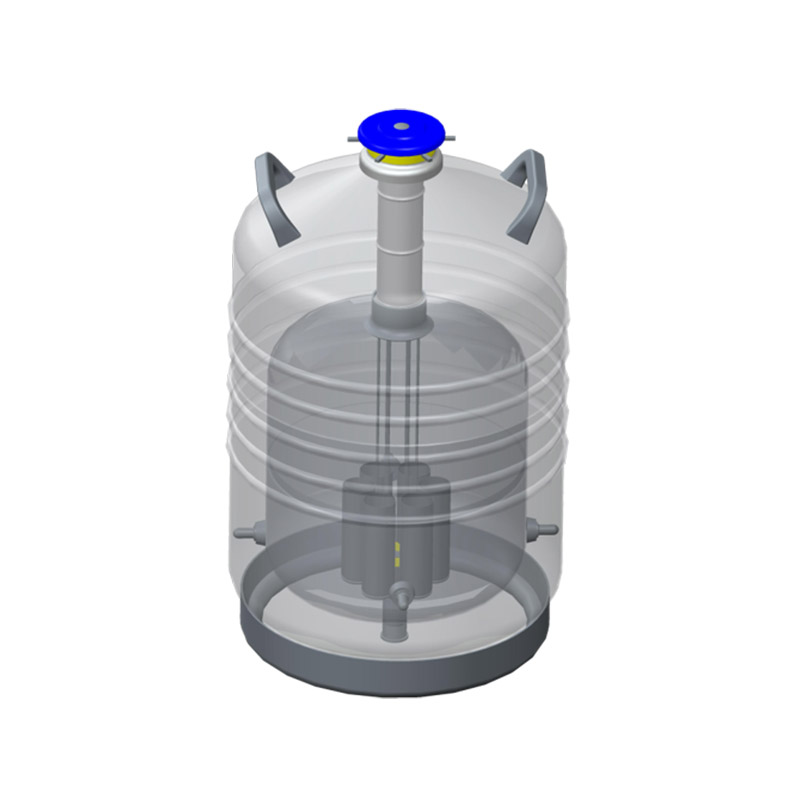

Static Storage Series Liquid Nitrogen Container

Discover high-performance static storage series liquid nitrogen containers designed for the long-term preservation of biological samples. Our containers feature advanced insulation technology to maintain extremely low temperatures, ensuring the in...

Control Rate Freezer

Discover our advanced Control Rate Freezer designed for precise and reliable cryopreservation. Ideal for laboratories, biobanking, and cell therapy, our freezer ensures optimal sample integrity with customizable freezing profiles and enhanced data...

Crytherapy Chamber

Discover the transformative power of the Liquid Nitrogen Cryosauna Chamber. This advanced cryotherapy solution uses extreme cold to promote recovery, reduce inflammation, and enhance overall wellness. Ideal for athletes and wellness enthusiasts, o...

Lab Series Liquid Nitrogen Container

Discover efficient and reliable Lab Series Liquid Nitrogen Containers designed for the safe storage and handling of liquid nitrogen in laboratory settings. Featuring advanced insulation technology, these containers minimize evaporation and maintai...

Transportation Series Liquid Nitrogen Container

Explore the benefits of using a Transportation Series Liquid Nitrogen Dewar made from high-strength aluminum for safe and efficient cryogenic storage and transport. Designed for preserving biological samples, industrial gases, and other temperatur...

Microbulk Tank

Discover efficient and reliable cryogenic microbulk tanks designed for the safe storage of liquefied gases such as nitrogen, oxygen, and argon. Featuring advanced insulation technology, our microbulk tanks maintain extremely low temperatures to en...

Liquid Helium Dewar

Explore our premium Liquid Helium Dewars designed for efficient cryogenic storage and transport. Our vacuum-insulated dewars ensure minimal helium loss and maintain extremely low temperatures, making them ideal for scientific, medical, and industr...

Cryogenic Protective Gaiter

Cryogenic protective gaiters offer comprehensive lower leg and feet protection for workers in healthcare, aerospace, and chemical processing industries. Featuring advanced insulation and waterproofing, these gaiters prevent frostbite and cold bur...

loading...

已经是到最后一篇内容了!

WOBO Industrial Group Cryochains

WOBO Industrial Group Cryochains