Liquid Nitrogen Tunnel Freezer

Innovative Freezing Technology for Enhanced Food Safety and QualityA Liquid Nitrogen Tunnel Freezer is a specialized piece of equipment used to rapidly freeze products by exposing them to extremely low temperatures using liquid nitrogen.

You may also be interested in these products.

Vehicle-Mounted Liquid Hydrogen Cylinder

Discover high-performance Vehicle-Mounted Liquid Hydrogen Cylinders designed for efficient fuel storage and transport. Our vacuum-insulated cylinders ensure minimal hydrogen loss and maintain extremely low temperatures, making them ideal for hydro...

Liquid Nitrogen Doser

Discover the advanced liquid nitrogen dosers that offer precise and reliable dispensing for a wide range of applications. Whether in the food industry, medical field, or scientific research, our liquid nitrogen dosers ensure efficient and safe han...

Biological Sample Transport Cart

Ensure the safe and efficient transport of biological and clinical samples with our advanced Biological Sample Transport Cart. Designed with secure compartments and temperature control options, this cart maintains sample integrity and safety durin...

YDD series biobank freezer

Discover advanced biobank freezers designed for reliable ultra-low temperature storage of biological samples. Our freezers ensure the integrity and longevity of DNA, RNA, proteins, and cell cultures with cutting-edge insulation and cooling technol...

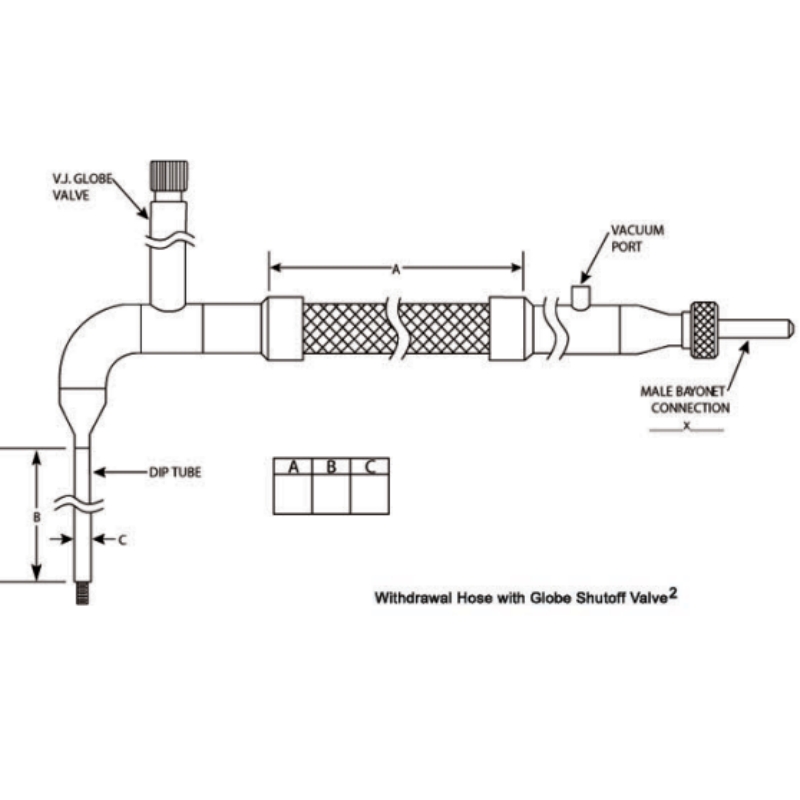

Vacuum Insulated Flexible Hose

Discover the benefits of using Cryogenic Vacuum Insulated Flexible Hoses for the safe and efficient transfer of liquid nitrogen, helium, and oxygen, etc. These hoses feature advanced vacuum insulation technology to minimize heat transfer, ensuring...

Wide Mouth Series Liquid Nitrogen Container

Discover the advantages of using a Wide Mouth Liquid Nitrogen Dewar made from durable aluminum alloy for efficient cryogenic storage and transport. Ideal for preserving biological samples, semen and stem cell, these vacuum-insulated containers mai...

Liquid Helium Transport Pipeline

Explore the benefits of using Liquid Helium Transport Pipelines with advanced vacuum insulation technology for safe and efficient helium distribution. These pipelines maintain cryogenic temperatures, ensuring the integrity and safety of liquid hel...

Control Rate Freezer

Discover our advanced Control Rate Freezer designed for precise and reliable cryopreservation. Ideal for laboratories, biobanking, and cell therapy, our freezer ensures optimal sample integrity with customizable freezing profiles and enhanced data...

loading...

已经是到最后一篇内容了!

WOBO Industrial Group Cryochains

WOBO Industrial Group Cryochains