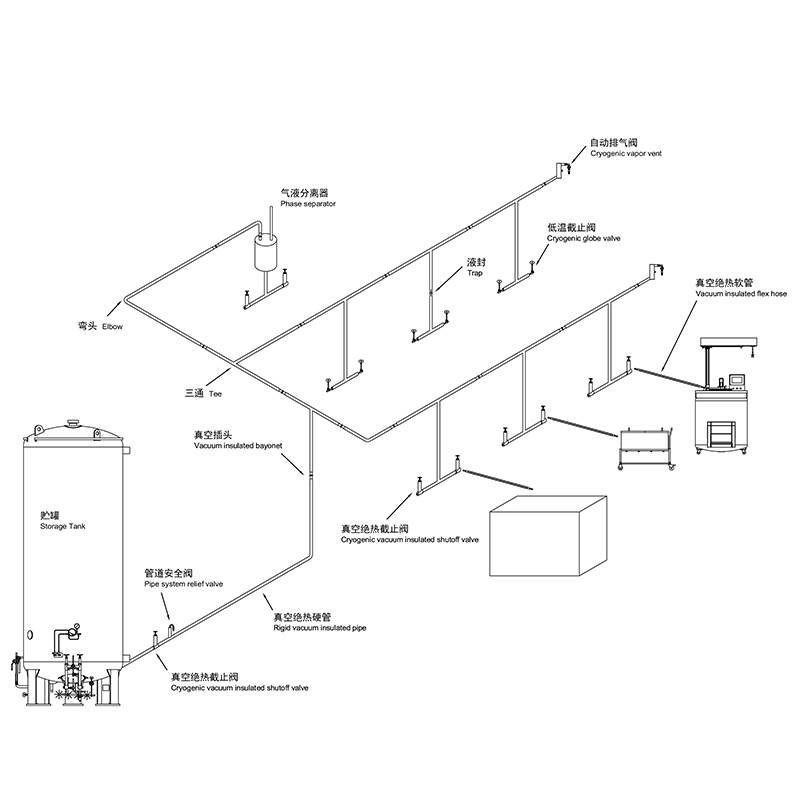

Cryogenic Piping Engineering

Comprehensive Cryogenic Piping Engineering for Industrial NeedsLow-temperature pipeline engineering involves the design, construction, and maintenance of pipelines that operate at extremely low temperatures. These pipelines are essential for transporting cryogenic fluids such as liquefied natural gas (LNG), liquid nitrogen, and other industrial gases. The engineering process ensures the integrity and efficiency of the pipelines under harsh conditions, preventing leaks and maintaining the desired temperature.

You may also be interested in these products.

In-Tank Transfer Pump

The in-tank transfer pump offers precision fluid handling and energy efficiency, making it the ideal solution for industrial applications, storage systems, and fluid transportation tasks.

Biological Sample Transport Cart

Ensure the safe and efficient transport of biological and clinical samples with our advanced Biological Sample Transport Cart. Designed with secure compartments and temperature control options, this cart maintains sample integrity and safety durin...

Cryogenic Insulated Cylinder

Discover high-performance cryogenic insulated cylinders designed for the safe and efficient storage and transport of liquefied gases such as nitrogen, oxygen, and carbon dioxide. Featuring advanced insulation technology, our cylinders maintain ext...

Liquid Hydrogen Transport Pipeline

Explore the benefits of using Liquid Hydrogen Transport Pipelines with advanced vacuum insulation technology for safe and efficient hydrogen distribution. These pipelines maintain cryogenic temperatures, ensuring the integrity and safety of liquid...

Cryogenic Protective Gloves

Ensure maximum safety and protection with our Cryogenic Protective Gloves, designed for handling extremely cold materials like liquid nitrogen. These gloves provide superior thermal insulation and dexterity, essential for laboratory, industrial, a...

Dry Shipper

Discover the benefits of using dry shippers for secure and contamination-free transport of biological samples at cryogenic temperatures. Ideal for reproductive medicine, biobanking, and research, dry shippers maintain ultra-low temperatures withou...

Liquid Hydrogen Tank Container

Explore the benefits of using Liquid Hydrogen Tank Containers with advanced vacuum insulation technology for safe and efficient hydrogen storage and transport. These containers maintain cryogenic temperatures, ensuring the integrity and safety of ...

Portable Series Liquid Nitrogen Container

Discover the benefits of using a Portable Liquid Nitrogen Dewar made from durable aluminum alloy for safe and efficient cryogenic storage and transport. Ideal for preserving biological samples, semen, and stem cell, these vacuum-insulated containe...

loading...

已经是到最后一篇内容了!

WOBO Industrial Group Cryochains

WOBO Industrial Group Cryochains